High resolution optics

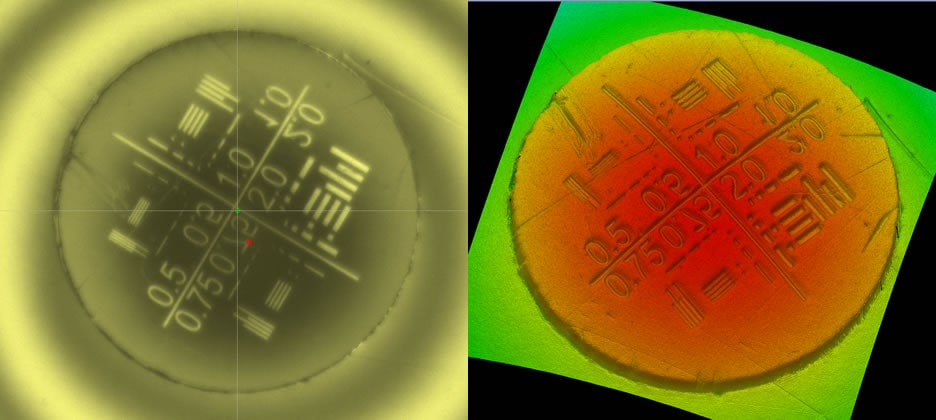

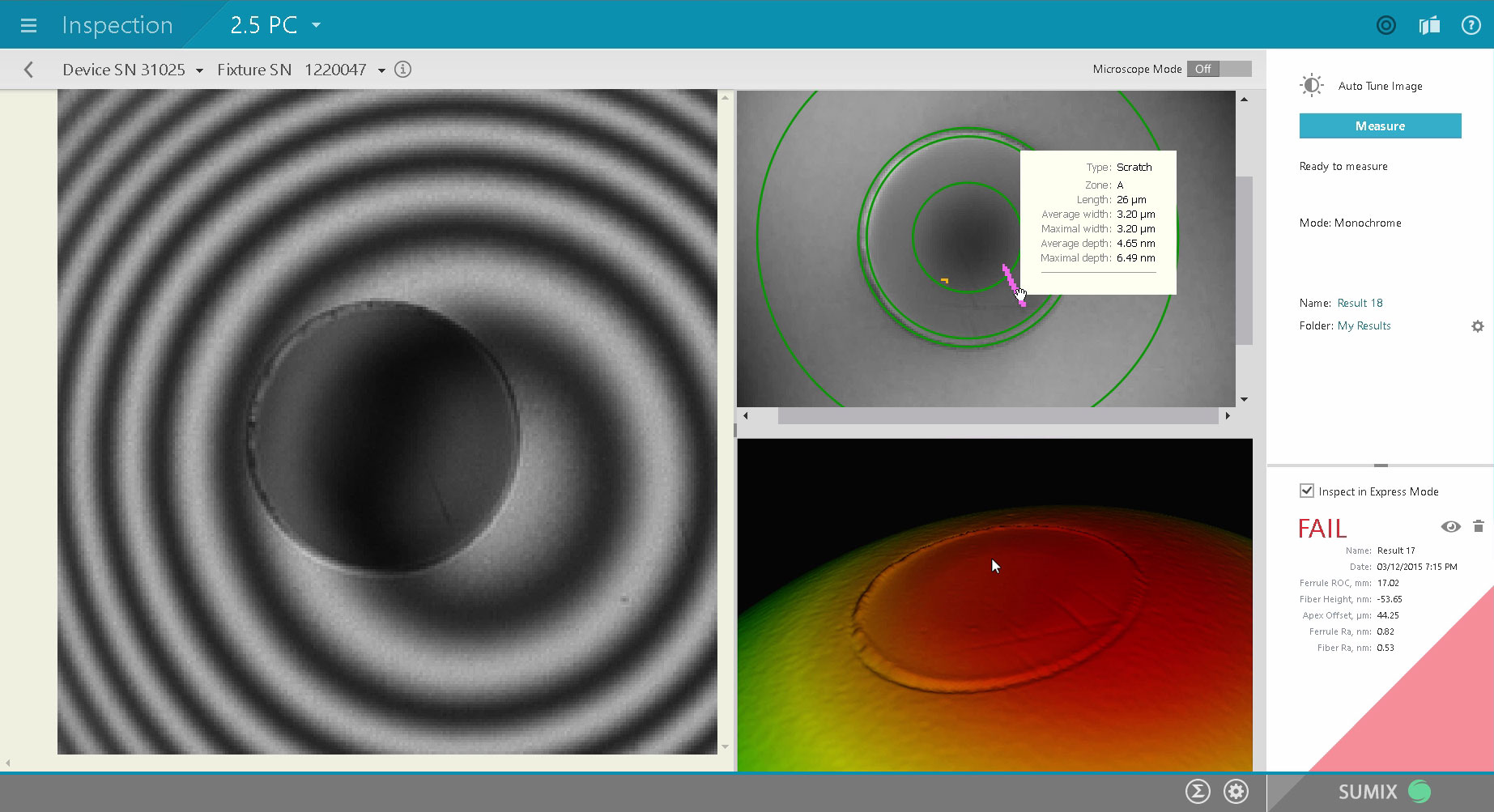

Resolve surface details as small as 0.53 μm on single fiber connectors and 1.4 μm on multi-fiber connectors.

Resolve surface details as small as 0.53 μm on single fiber connectors and 1.4 μm on multi-fiber connectors.

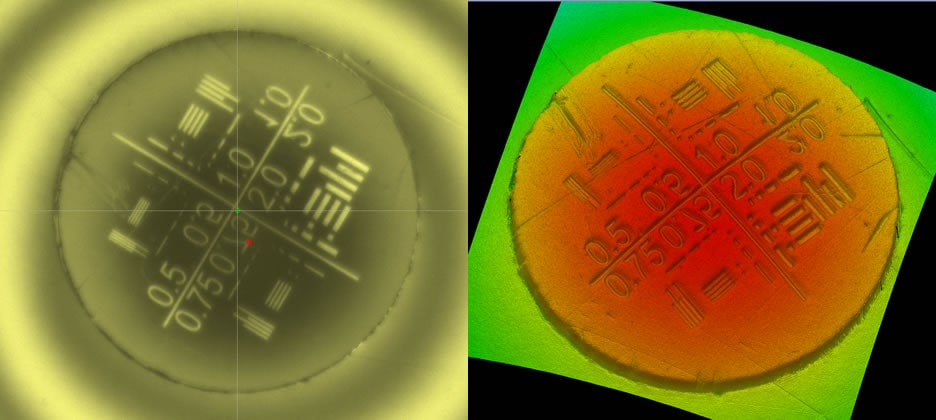

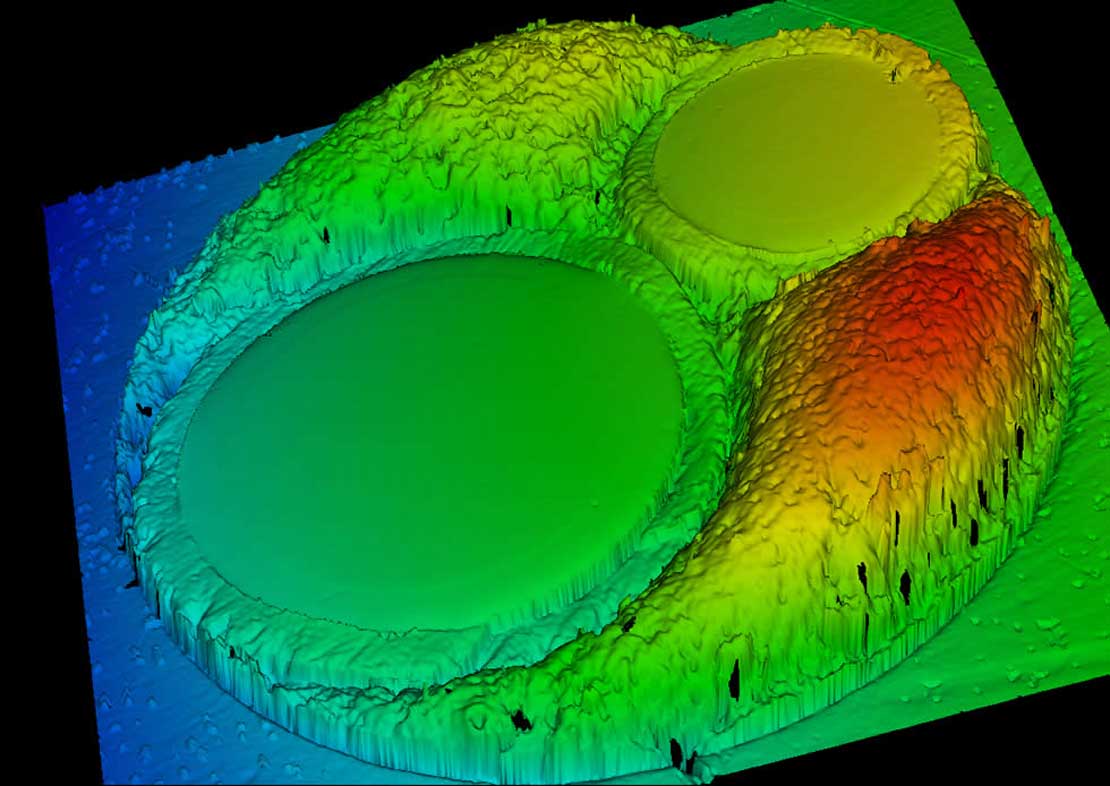

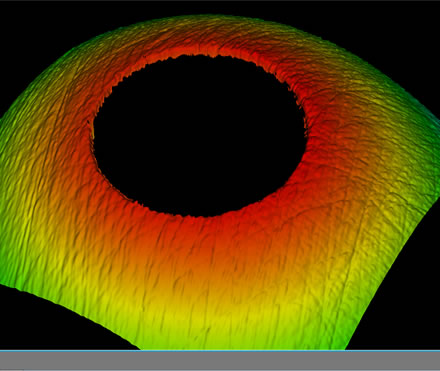

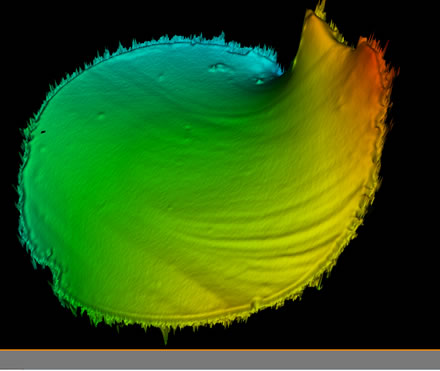

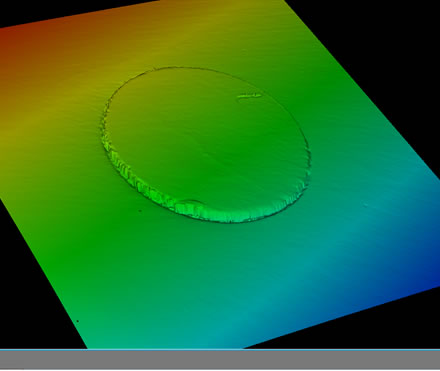

The 3D surface view enables you to see the volume image of the fiber and the ferrule and to examine surface details.

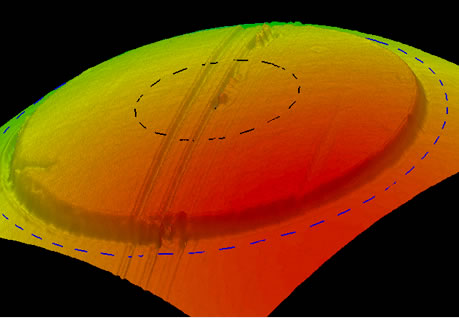

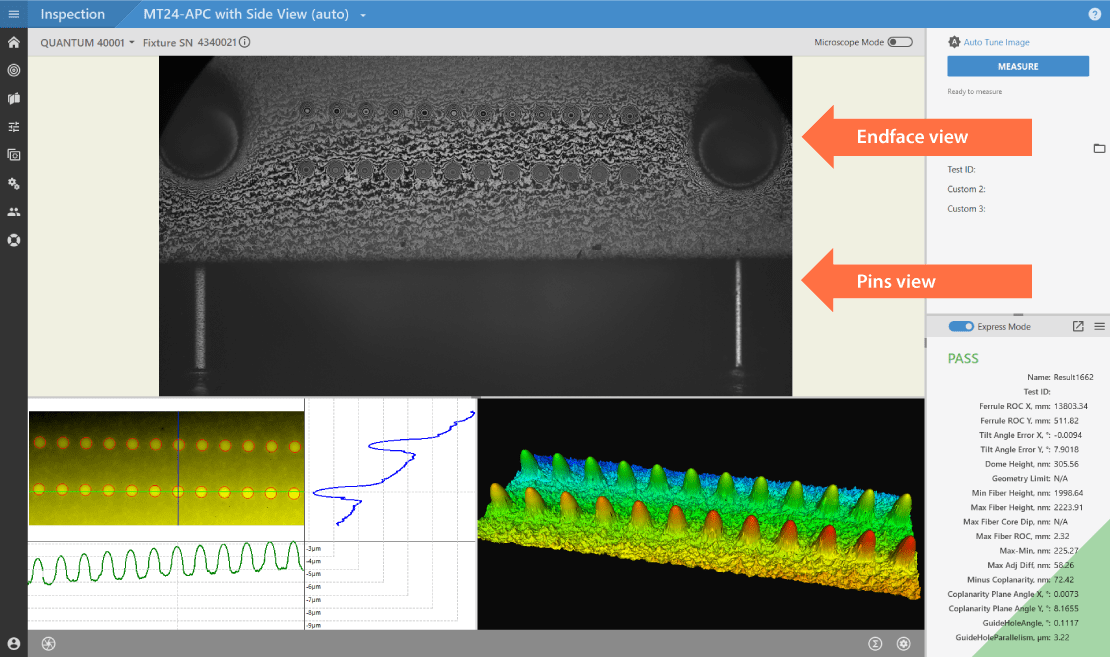

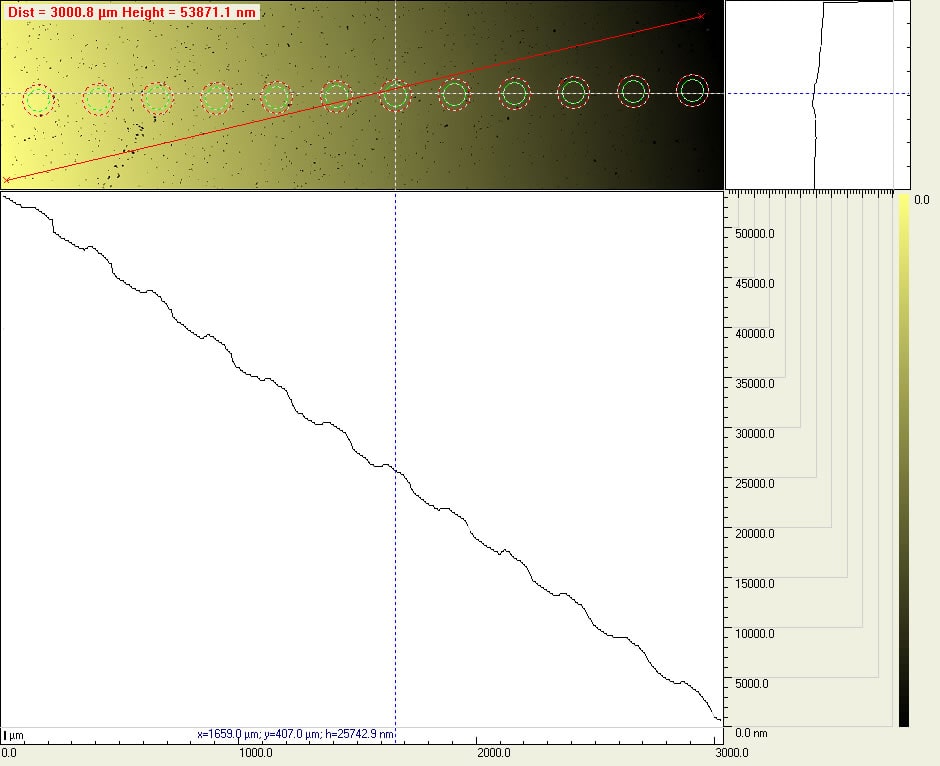

Measure connectors from guide hole to guide hole.

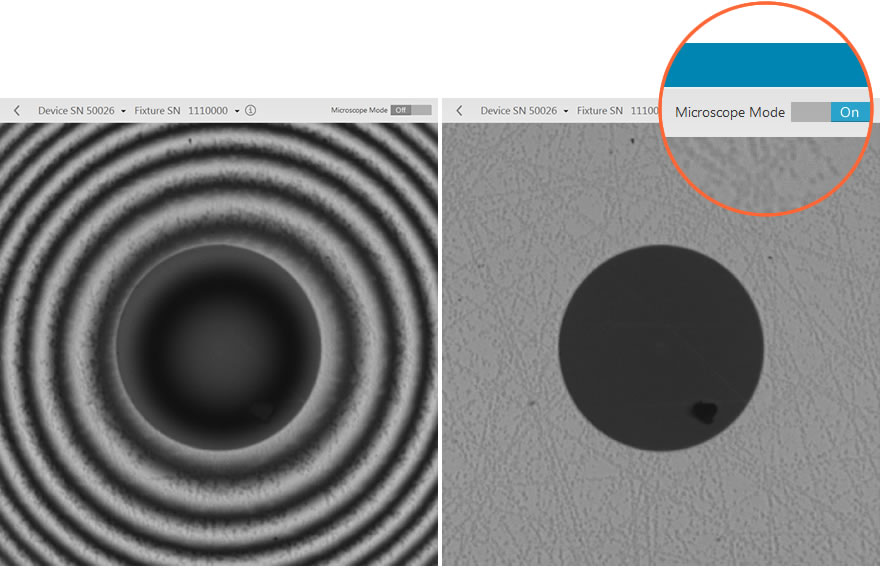

Inspect buffer zones, materials with different reflectivity (e.g. metal ferrule and plastic fiber).

Measure angles and parallelism of guide holes along with the standard geometry parameters using Side+Front View technology

Minimize operator’s actions to just one click.

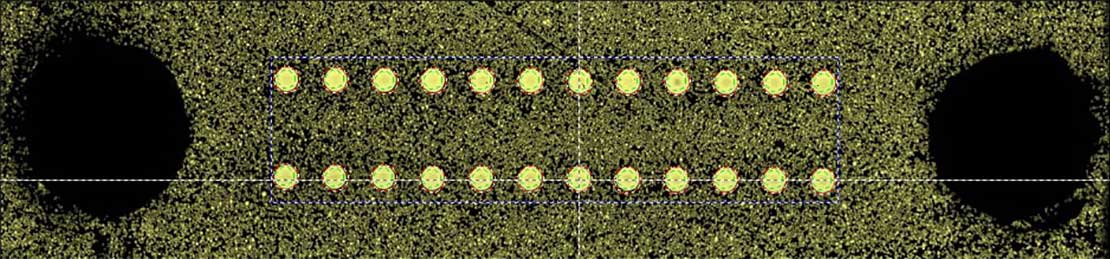

Test single fiber and multi-fiber ferrules and patchcords along with bare ferrules, cleaved bare fiber and flat polish connectors.

Identify scratches as small as 0.53 microns.

* MAX-QS+, MAX-QM-B+ and MAX-Quantum.

Visually inspect connector end face prior to measurement

* Available with MAX-QS+, MAX-QM-B+ and MAX-Quantum.

Forget about tedious every-day calibration.

Inspect single and multi-fiber connectors, ferrules, mechanically and laser-cleaved bare fibers, MS termini, both PC and APC.

Measure large height differences.

* <100 µm available by default. >100 µm - for special connectors/tasks (software adjustment required).

Store measurement data from all local sites in one place and easily integrate Sumix equipment into your manufacturing systems.