Measure Angles and Parallelism of Guide Holes along with the standard geometry parameters using Side+Front View technology

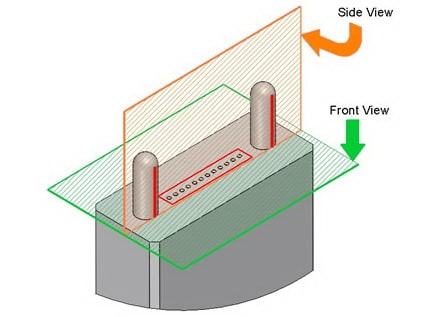

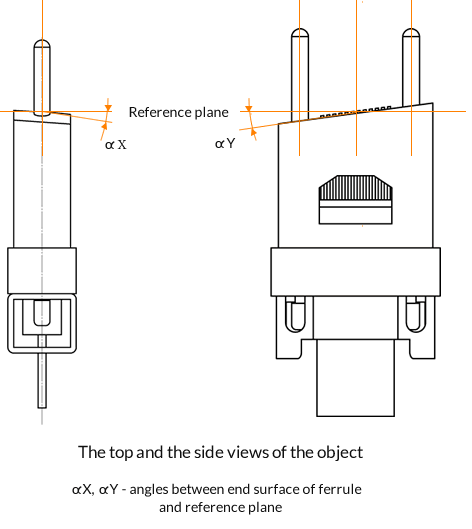

What is the Side+Front View method?

The patented new approach for the inspection of MTP/MPO patch cords and its unique MTP/MPO fixture design provide simultaneous interferometric scanning from two perspectives: Side and Front views.

The Side+Front View method allows for measurement of endface angles with respect to average guide pin orientations. In addition, X/Y angles and parallelism of guide holes are calculated in compliance with IEC 61755-3-32 standard that requires guide holes parallelism to be better than 0.012mm and the endface angle with respect to the average of the guide holes to be within tolerance of ±0.15 degree.

The technology also addresses the many variables which influence the results of MTP/MPO geometric measurements while reducing both the need for precise ferrule positioning and attention to cable management.

What are the benefits?

- Non-contact method reduces risk to guide holes;

- Reduction of operator-error;

- Measurements un-affected by cable strain;

- Increased accuracy by independence of the ferrule parameters;

- User-friendly calibration and verification;

- Control of additional IEC parameters defining guideholes quality.

What equipment do I need?

MAX-SVF-series fixtures can be used with either Sumix MAX-QM+ or MAX-QUANTUM model interferometers.

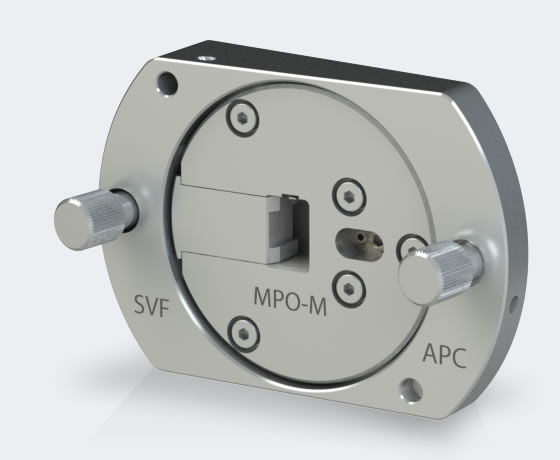

MAX-SVF-MPO-APC-M

Fixture for inspection of male MTP®/MPO patchcords, APC type, and measuring guide holes angles and parallelism. Suitable for 16-32 fiber and 12-72 fiber MTP®/MPO. Female MTP®/MPO patch cords can be inspected if pins are inserted manually (order AC-MPO-PI pin insertion tool).

Needs calibration with a reference connector (order MAX-REF-SVF-MPO-APC-M).

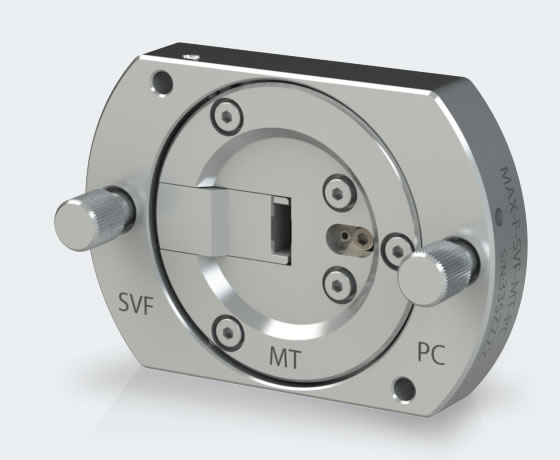

MAX-SVF-MPO-PC-M

Fixture for inspection of male MTP®/MPO patchcords, PC type, and measuring guide holes angles and parallelism. Suitable for 16-32 fiber and 12-72 fiber MTP®/MPO. Female MTP®/MPO patch cords can be inspected if pins are inserted manually (order AC-MPO-PI pin insertion tool).

Needs calibration with a reference connector (order MAX-REF-SVF-MPO-PC-M).

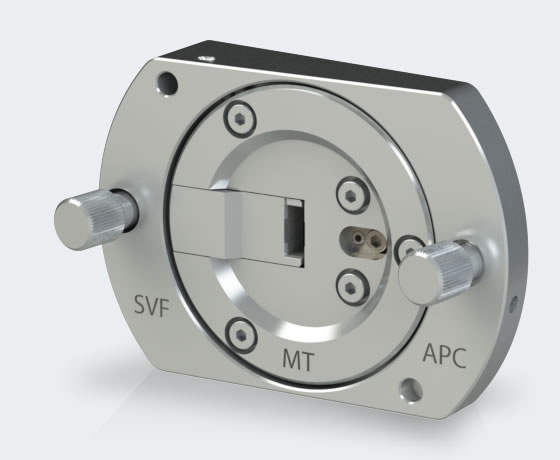

MAX-SVF-MT-APC

Fixture for inspecting endface geometry of MT/APC ferrules (with pins inserted) including guide hole angles and parallelism. Suitable for 16-32 fiber and 12-72 fiber ferrules.

Needs calibration with a reference connector (order MAX-REF-SVF-MT/APC).

MAX-SVF-MT-PC

Fixture for inspecting endface geometry of MT/PC ferrules (with pins inserted) including guide hole angles and parallelism. Suitable for 16-32 fiber and 12-72 fiber ferrules.

Needs calibration with a reference connector (order MAX-REF-SVF-MT/PC).

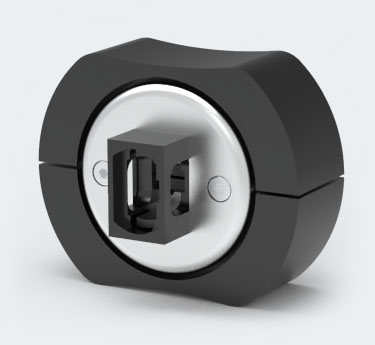

AC-MPO-PI

Pin insertion tool to inspect female MPO patch cords with MAX-SVF-MPO-PC-M and MAX-SVF-MPO-APC-M fixtures

For more information please contact:

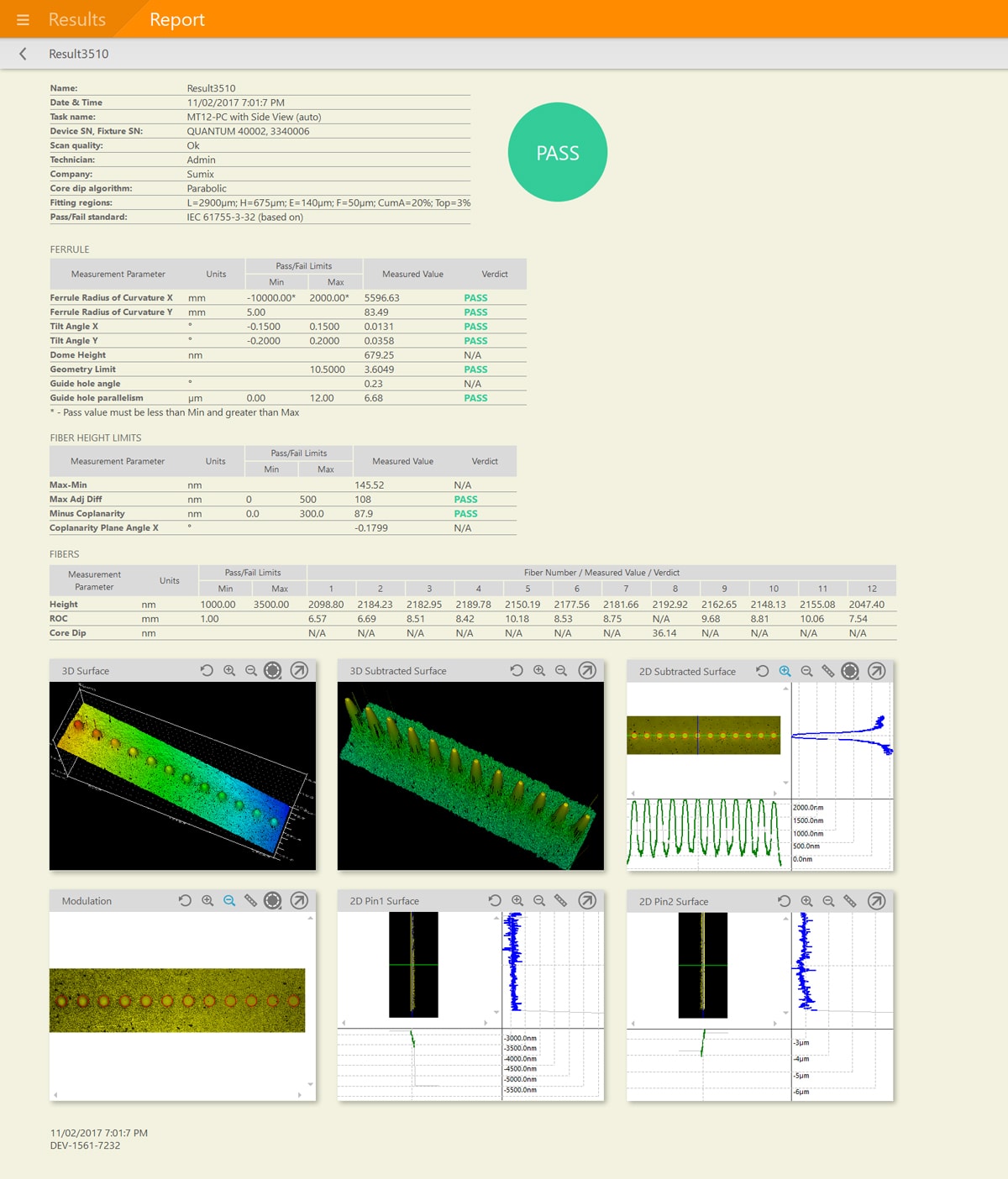

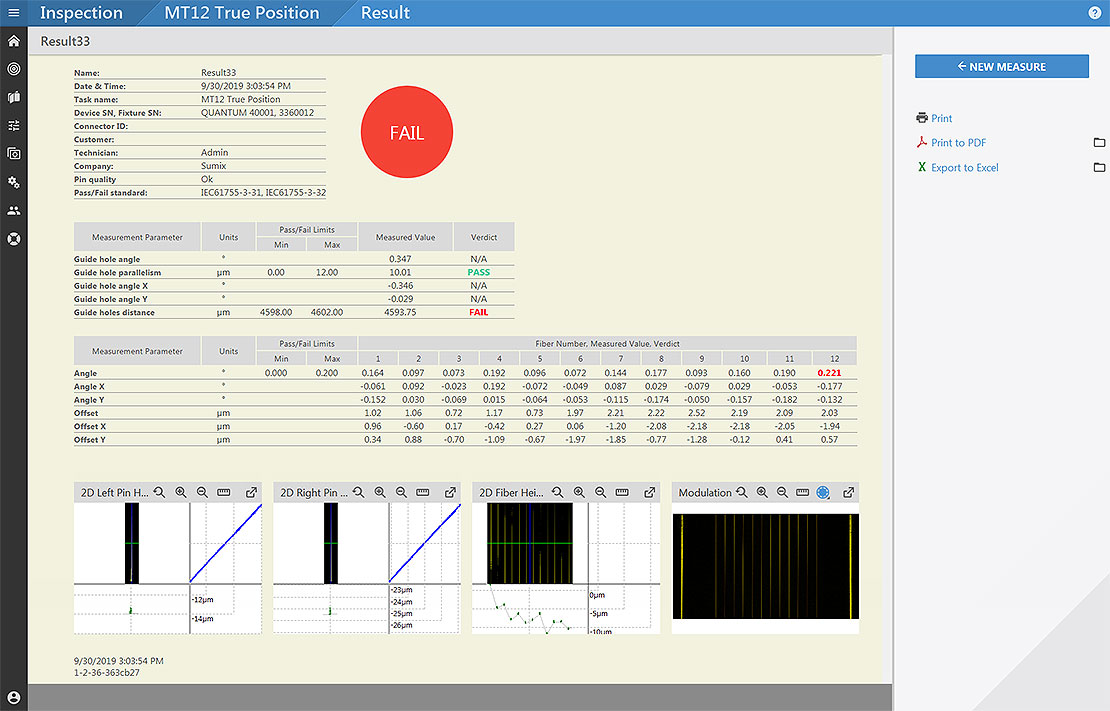

Inspect Angles and Offset of Fiber Holes, Angles and Parallelism of Guide Holes using True Position™ fixture

What is special about the True Position™ fixture?

True Position™ fixture from Sumix provides for interferometric scanning from the side perspective and replaces time-consuming procedures carried-out by high-cost stationary equipment (like 3D computed tomography) to ensure the quality of bare MT ferrules and their compliance with the industry standards.

Applications

- For ferrule manufacturers to control and certify geometry of bare ferrules.

- For patchcord manufacturers to perform receiving inspection.

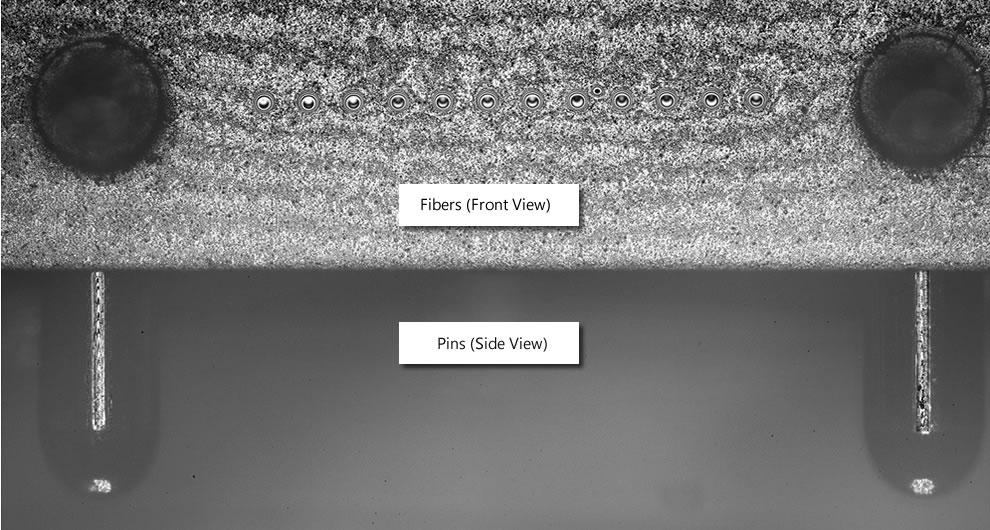

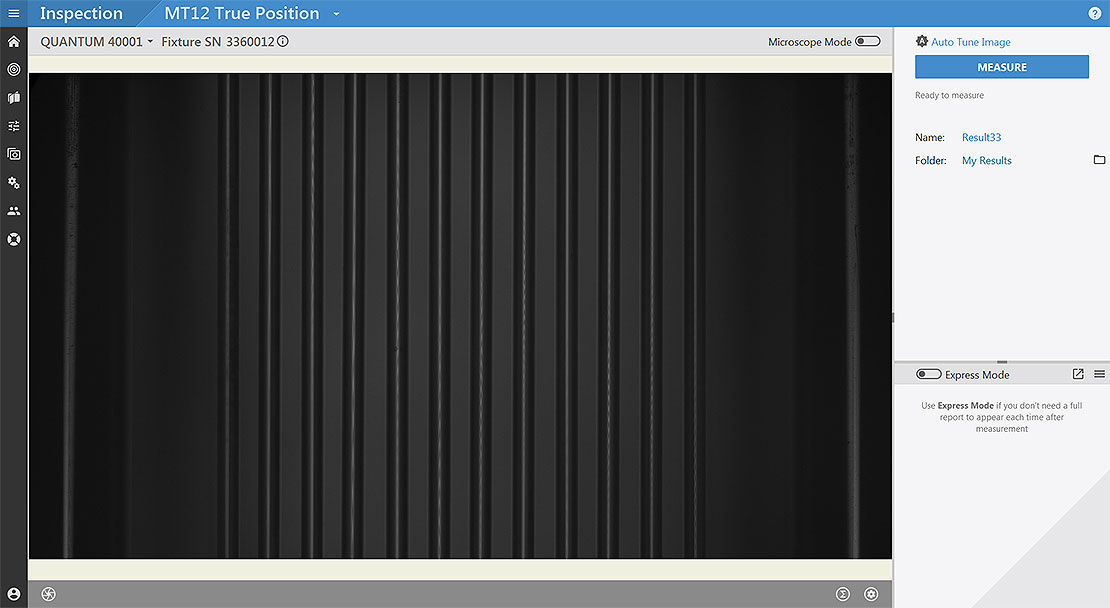

Live view of bare MT ferrule with pins and fibers inserted

True Position™ measurement report

What equipment do I need?

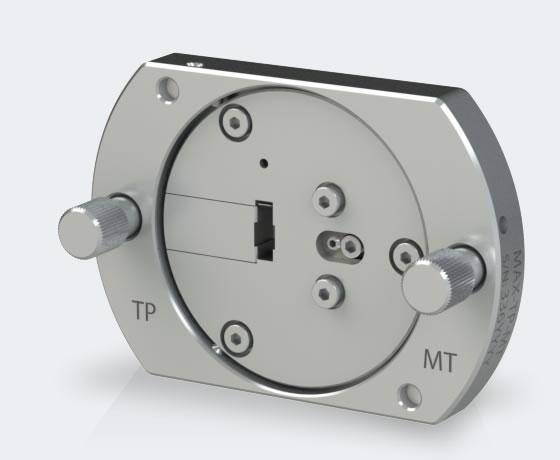

MAX-TP-MT, MAX-TP-MT16 fixtures and MAX-QUANTUM interferometer.

MAX-TP-MT

Fixture for measuring angles and offset of fiber holes, angles and parallelism of guide holes of bare MT12 ferrules (incl. pre-angled ones). To be used with MAX-Quantum only.

MAX-TP-MT16

True Position™ fixture for inspecting angles and offset of fiber holes, angles and parallelism of guide holes in bare MT16 PC ferrules (with a permanent license).

For more information please contact: