MAX-Quantum is a high-end automated interferometer for inspection of single and multi-fiber connectors of MTP®/MPO, ST, FC, SC, LC, MU, E2000™ types as well as MT, MT-RJ ferrules in a single scan.

MAX-Quantum provides simultaneous end-face geometry inspection, anomalies detection and guide hole parallelism and angles measurement.

This interferometer features high optical resolution, autofocus and a large field of view with the ability to test 16 fibers per row.

More images you can find here

MAX-Quantum interferometric system includes:

Fixtures and other accessories should be ordered separately.

MPO-Verifier illumination module combined with MAX-Quantum is a single solution for end-to-end polarity validation, continuity confirmation and endface inspection of MPO cables.

Purchased with an interferometer

(i) e-mail support for all technical issues relating to the use of the interferometer and the MaxInspect software within one (1) business day of receipt;

(ii) all revisions and updates to the MaxInspect software;

(iii) remote hardware and software demonstration, help desk and video tutorials;

(iv) remote hardware troubleshooting;

(іv) providing a loaner unit for the period of repair or calibration (upon availability and if requested).

Extending the Support Plan is optional. If the Support Plan is extended for next year continuously (without a break in support), a 50% discount for the Support Plan applies.

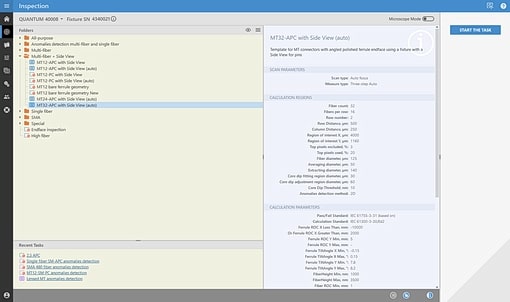

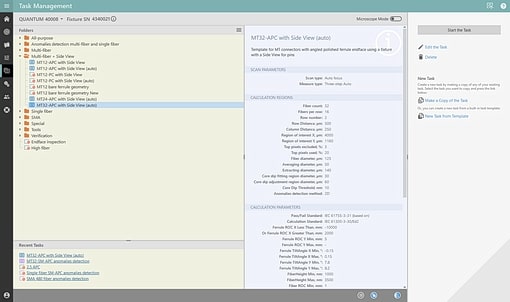

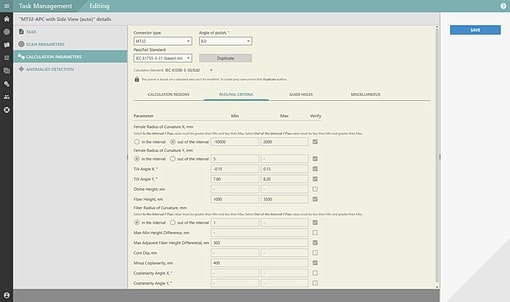

MaxInspect™ Software

Home screen

Task list

Variety of tasks for all major connector types per IEC/Telcordia industry standards. You may choose to see only active tasks supported by your equipment.

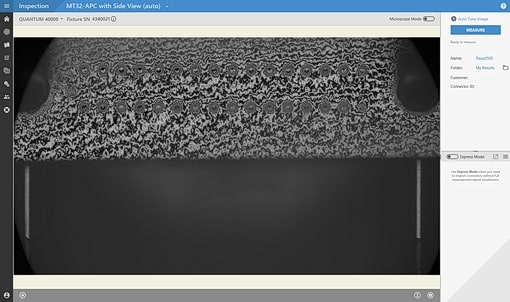

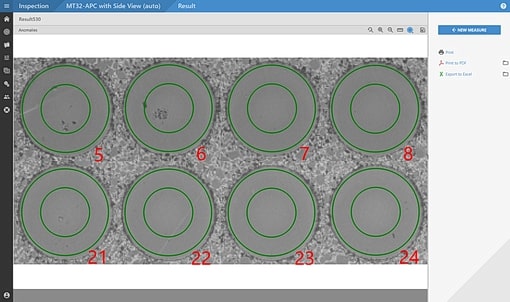

Side+Front View of MT 32 connector

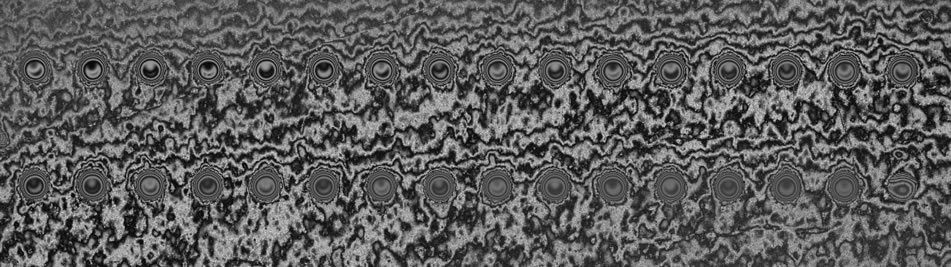

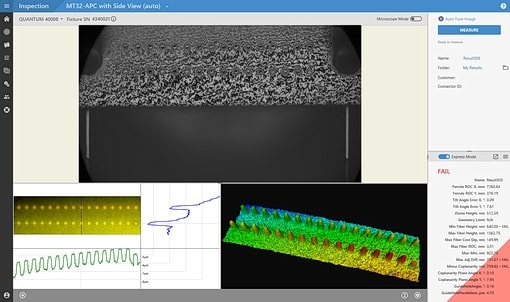

Live View

Side+Front View of MT 32 connector

Express report

Side+Front View of MT 32 connector

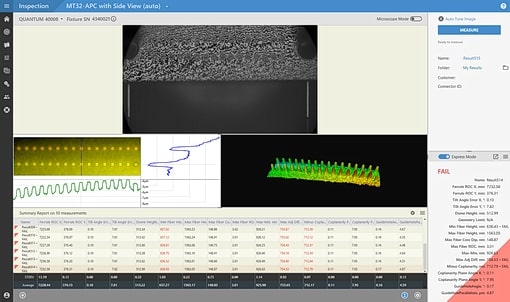

Express and summary reports

Side+Front View of MT 32 connector

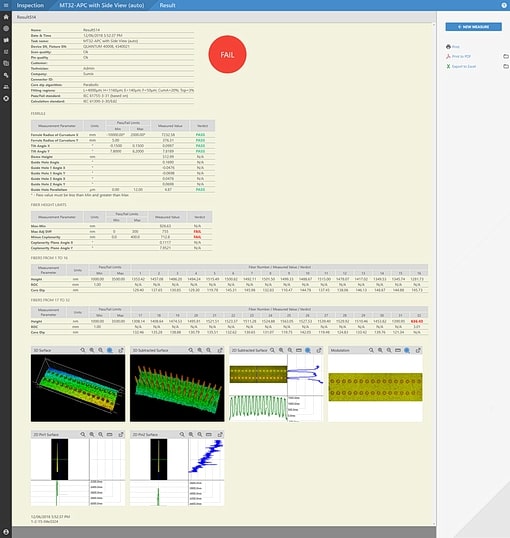

Full report

Side+Front View of MT 32 connector

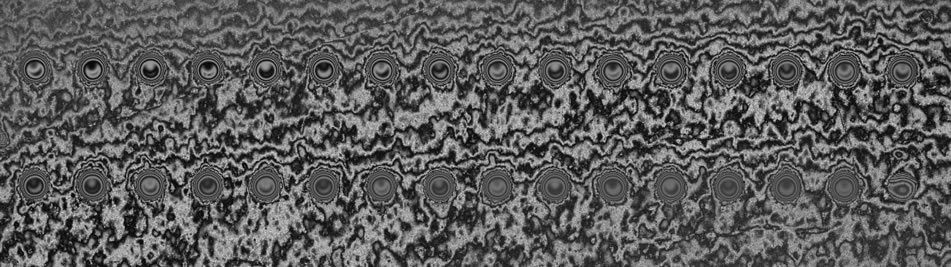

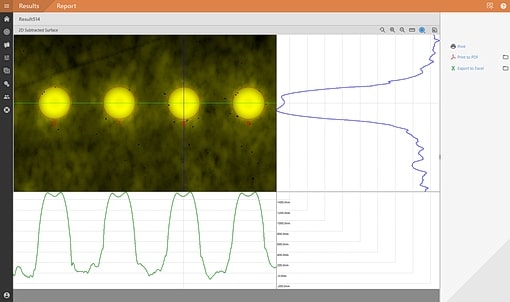

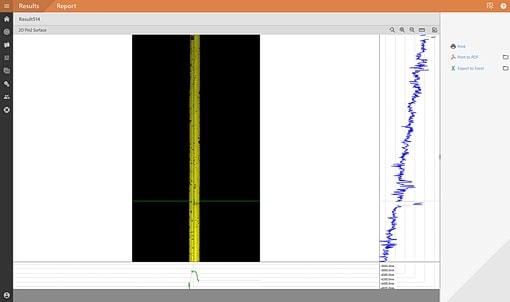

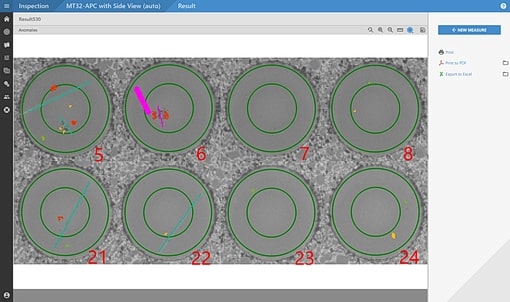

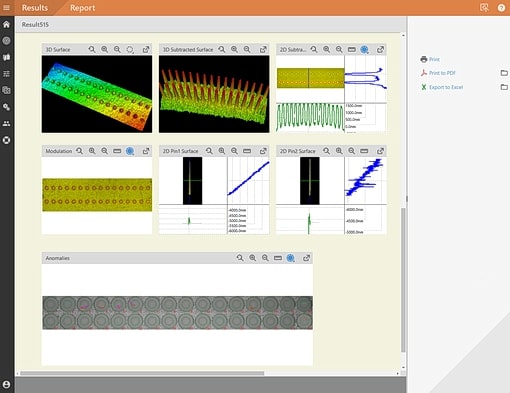

2D substructed surface

Side+Front View of MT 32 connector

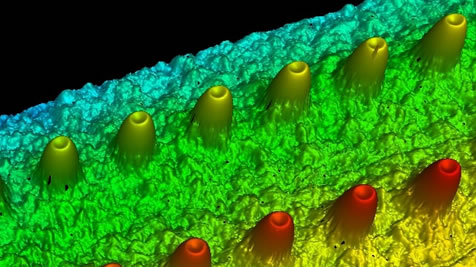

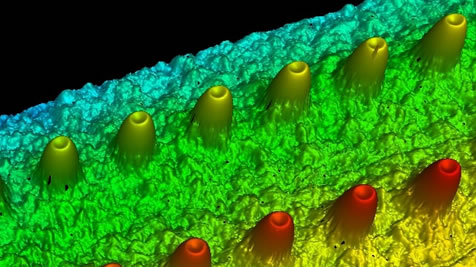

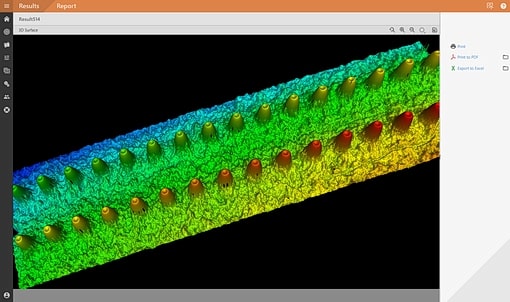

3D surface

Side+Front View of MT 32 connector

2D pin

Side+Front View of MT 32 connector

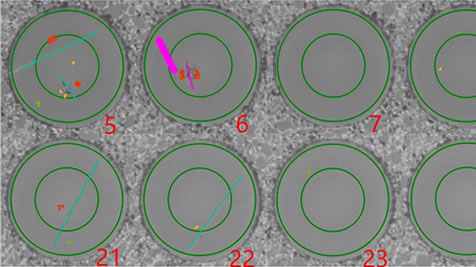

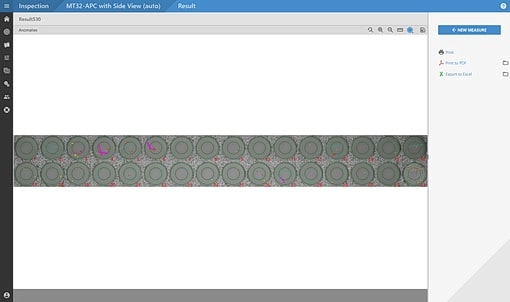

Anomalies image

Side+Front View of MT 32 connector

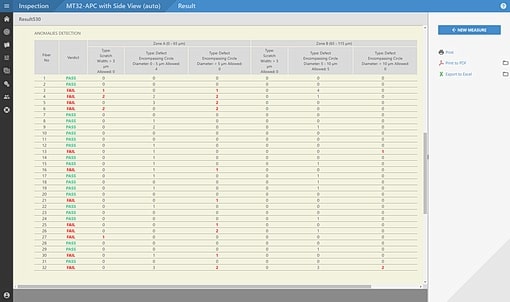

Anomalies report

Side+Front View of MT 32 connector

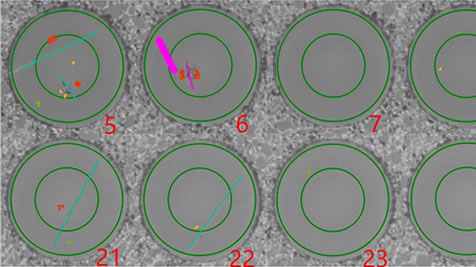

Zoomed anomalies image

Side+Front View of MT 32 connector

Zoomed images with indicated anomalies

Side+Front View of MT 32 connector

Set of images in report

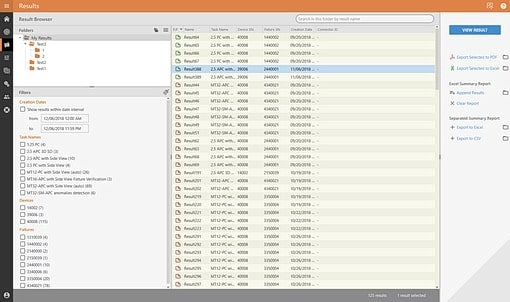

Result Browser

MaxInspect™ Software

Task management

Side+Front View of MT 32 connector

Task editing

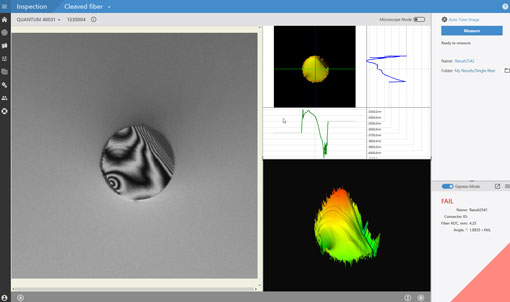

Inspection of cleaved bare fiber

Live view and measurement result

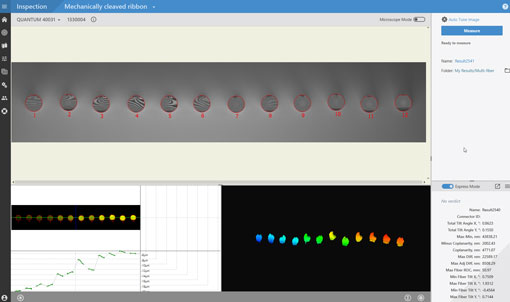

Inspection of cleaved fiber ribbon

Live view and measurement result

E2000 is a trademark of Diamond SA.

MTP is a registered trademark of US Conec Ltd.

CS is a registered trademark of Senko Advanced Components Inc.