Integration Tools

Sumix MaxInspect™ software provides the following tools for integration into customer’s manufacturing systems:

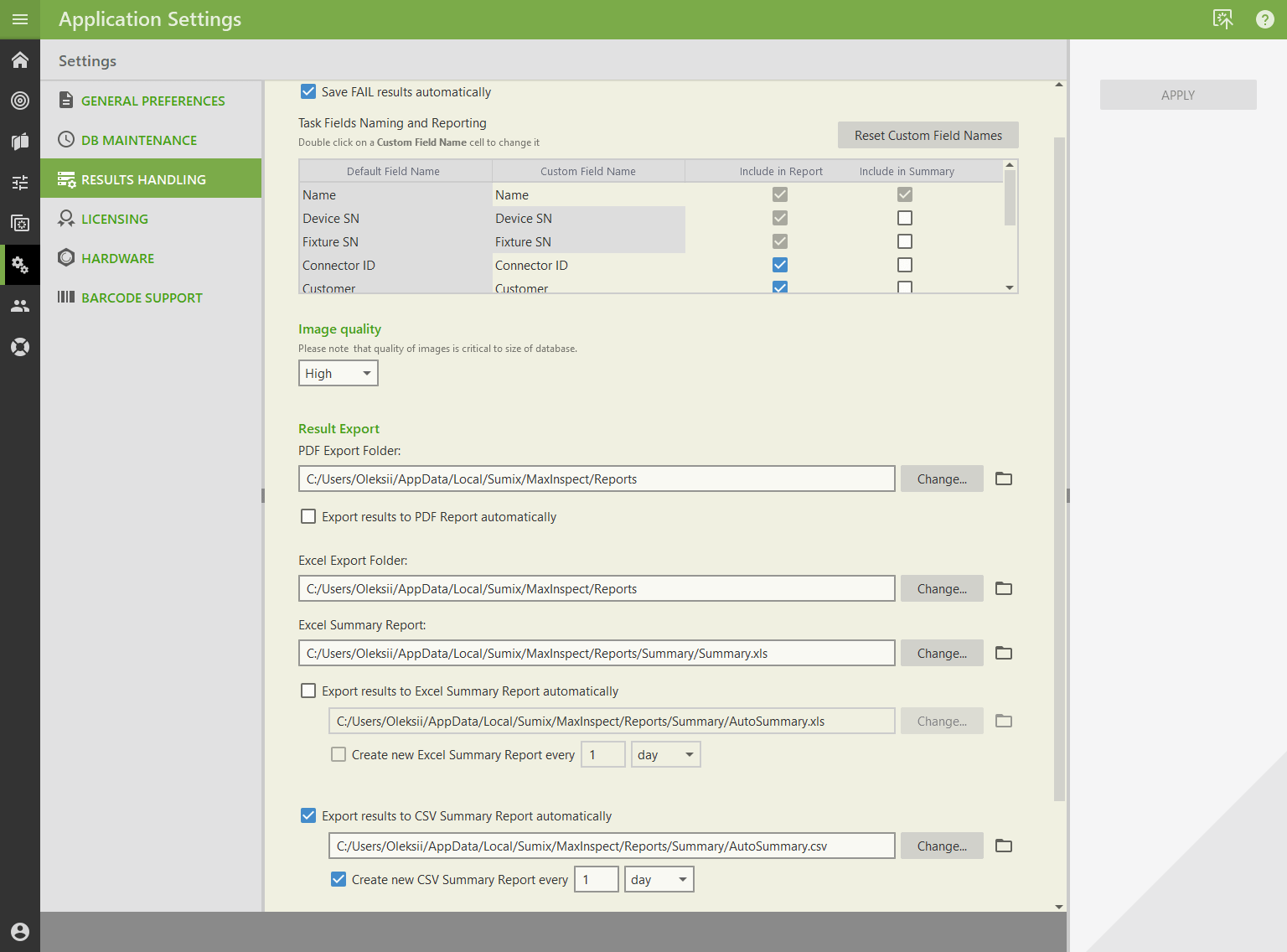

- Export of results to Excel/CSV files;

- Direct connection to customer's SQL database;

- MaxInspect™ WebSocket API;

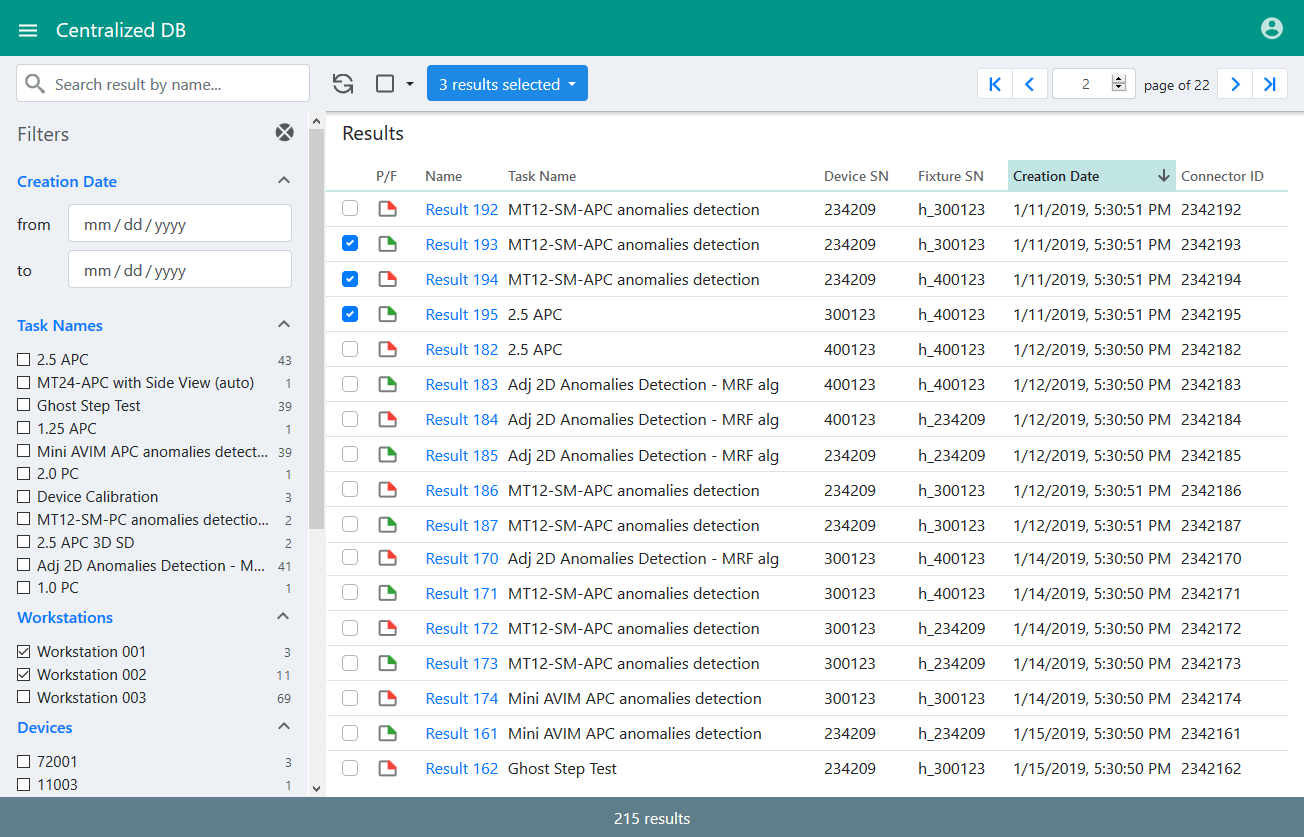

- Centralized MaxInspect™ database.

Main benefits:

- Interferometric and anomalies detection data can be gathered together with other measurement data (like OTDR data) or manufacturing process parameters;

- Results measured by local MaxInspect™ installations can be put into one centralized storage. That makes data integrated, storage robust, and gives a wide range of tools for data comparison and analysis.