WEBINAR

OIDA Sponsored Webinar:

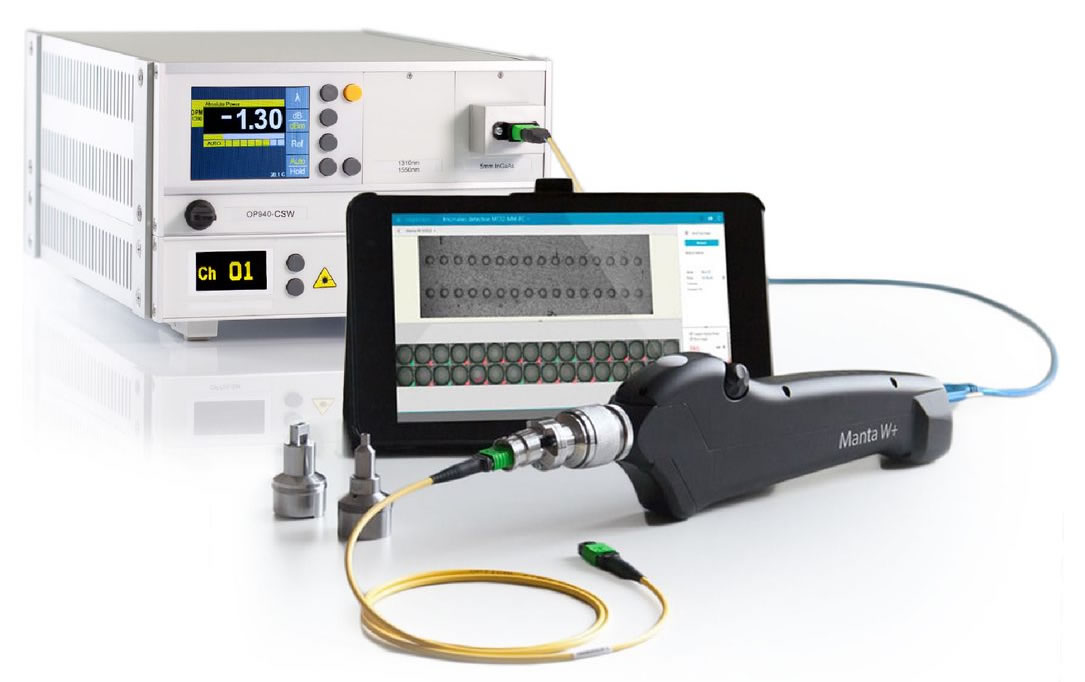

Key Attributes of Modern Cleaning and Inspection Solutions

April 7, 2021

Presented by: Optotest and Sumix

Watch webinar

Dirt and damage on fiber optic connections account for most problems in fiber networks. Cleaning and inspection are necessary protocols, and many solutions are available. Key differences among inspection solutions are under appreciated by many which could leave problems remaining undetected. This webinar explores these issues to enable attendees to make informed decisions about the solutions they implement for their needs.

Why is magnification a misleading specification for inspection equipment and which specifications matter more? When are automated inspection solutions more reliable than manual solutions? When is interferometry needed in addition to microscopy? Do expanded beam interconnects eliminate the needs for these protocols? These and other questions will be explored.

This webinar is brought to you jointly by OptoTest and Sumix. OptoTest manufactures and services calibrated test equipment used in the manufacture and qualification of fiber optic cables. Sumix manufactures high-precision microscopes and interferometers and actively participates in standards development for optical inspection systems.

Watch webinar

Recorded on 7 April 2021. Duration - 1 hour.

Attendee Questions & Answers

Are automated inspection solutions more reliable than manual solutions?

The biggest variable in a manual inspection is the operator. Differences in training, experience, job pressures or even tiredness will vary from person to person or from day to day. Inspection standards will also evolve over time and it takes effort to remain current. Automated inspection eliminates many of these variables and has other benefits:

- The Pass/Fail criteria is always the same, operator training or mood cannot effect results.

- Results are automatically stored and statistical analysis can be performed.

- Automated analysis exactly measures the size of defects and scratches while manual inspection often involves estimations.

- Results of inspection on manufacturer’s side will be comparable to the results obtained at the customer’s side.

How is the inspection tool calibrated?

Microscopes such as the Manta series are factory calibrated and do not require further adjusting or calibration at in regular use. The optical magnification does not change over the lifetime of the scope except in deliberate modification, damage or excessive environmental changes.

Can scratch artifacts be used to calibrate my microscope to ensure they are at their optimal resolution or are they only used test the capabilities of the microscope?

Scratch artifacts are not used for microscope calibration. These artifacts are helpful though to verify the ability of an optical microscope to detect scratches including those that are smaller than required by IEC standards.

For manufacturing, when does too high of a resolution become a problem? I can use the Manta W+ and the Polaris, one can give me a Pass and the other a Fail based on the resolution of the scratch detection. Would the Polaris be considered more severe and lead to rejected parts that the Manta W+ would pass?

Higher resolution increases repeatability of detection of small defects and repeatability of defect size interpretation. The Polaris scope is best for analyzing very small defects and defects that are on the edge of the pass/fail criteria. In practical use, the difference in resolution of Manta W+ and Polaris does not influence the Pass/Fail judgement.

For the Scratch, 0-3 µm - it's for the depth or width?

All these criteria apply to the width of the scratches.

Is it possible to control the probe by external software?

Yes, Sumix software comes with WebSocket API.

How repeatable and how accurate is the detection of scratches smaller than 3 µm in the zone A?

The detection repeatability for the scratches close to 3 µm is close to 100%. The Manta W+ microscope can detect scratches 1 µm wide and 8-10 nm deep with the repeatability up to 95%. Repeatability may decreases with lower contrast scratches. For instance, for very shallow scratches on rough surfaces in the presence of other defects.