Verification Artifacts for Microscopes

Here at Sumix, we have been carrying out extensive research activity in creating and testing microscope verification artifacts, as well as contributing to the development of industry standards.

By applying Nanoindentation technology, we have succeeded in producing artificial scratches and defects with controlled parameters. It has been confirmed that the ferrules with such surface features can be used as low-contrast artifacts to verify the accuracy of dimension measurements of real field defects and scratches.

So, what’s the breakthrough? Read more

Since such an artifact is a representation of a true-life inspection object, it allows to check what the system actually sees in contrast to what it “can see”. This way you can be confident that an optical microscope provides the necessary quality and sensitivity for visual inspection as well as reliable detection.

Currently we offer the following artifacts made with the help of Nanoindentation technology to verify how a microscope performs in terms of detectability.

Artifact for verification of Manta series microscopes

as per IEC 61300-3-35

The IEC 61300-3-35 (Edition 3.0) requires that on commissioning, and periodically during its life, the microscope system shall be validated. The validation procedure shall involve using validation artifacts with specific features. For verification of Manta series microscopes (Manta HM, Manta W+, Manta+V2) we offer the artifacts that outperform the minimum requirements set by the standard and feature two scratches of 1 μm width as well as controlled depth.

MNT-REF-2.5/PC-1UM

Verification artifact (2.5 PC ferrule) with artificial scratches on its end face made in accordance with the IEC 61300-3-35 standard. Designed to verify the system’s ability to detect scratches close to 1 µm in width. Produced with Nanoindentation technology.

Recommended for incoming and periodic verification.

MNT-REF-2.5/PC-1UM artifact end face image taken with a high-end fiber microscope.

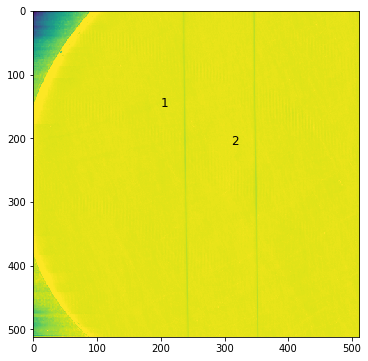

MNT-REF-2.5/PC-1UM artifact end face image taken with an AFM microscope.

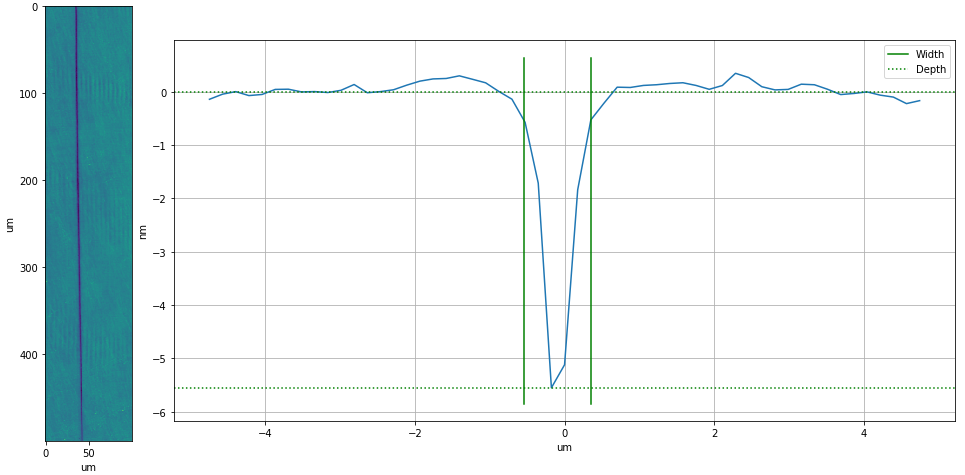

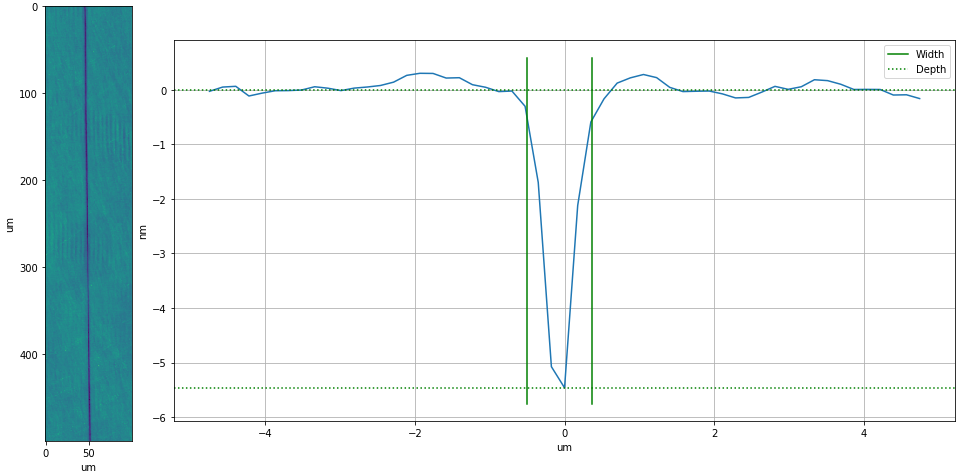

The report provided with a reference artifact contains the data from measurements made on Atomic Force Microscope (AFM) and Manta HM microscope with NIST traceable factory calibration.

Note: Sumix also has the capability to produce the scratches of custom width upon request (2 µm, 3 µm etc.).

Sample profile of scratch 1.

Sample profile of scratch 2.

Special-purpose artifacts for FOVIS

outlined in MIL-STD-1678

MIL-STD-1678-5 Measurement 5203 standard describes the artifacts for verification of Fiber Optic Video Inspection System (FOVIS).

In line with these requirements, Sumix offers:

MNT-REF-S0.75UM

Verification artifact (2.5 PC ferrule) with a pattern consisting of two scratches of 0.75 µm width, 5 nm depth, extended length, and 20 µm separation distance. Produced with Nanoindentation technology, PC polished. AFM measurement report included.

The artifact is low-contrast and can only be used with Polaris or other high-resolution microscopes.

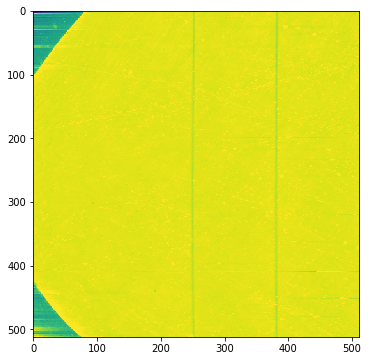

MNT-REF-S0.75UM artifact end face image taken with a high-end fiber microscope.

MNT-REF-S0.75UM artifact end face image taken with an AFM microscope.

MNT-REF-S2UM

Verification artifact (2.5 PC ferrule) with a pattern consisting of two scratches of 2 µm width, 15 nm depth, extended length, and 20 um separation distance. Produced with Nanoindentation technology, PC polished. AFM measurement report included.

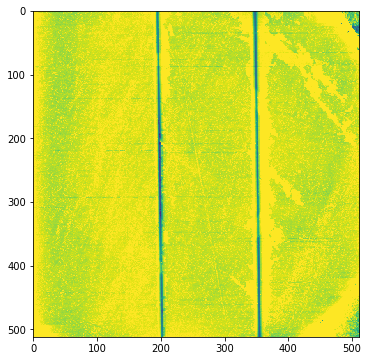

MNT-REF-S2UM artifact end face image taken with a high-end fiber microscope.

MNT-REF-S2UM artifact end face image taken with an AFM microscope.

MNT-REF-D1UM

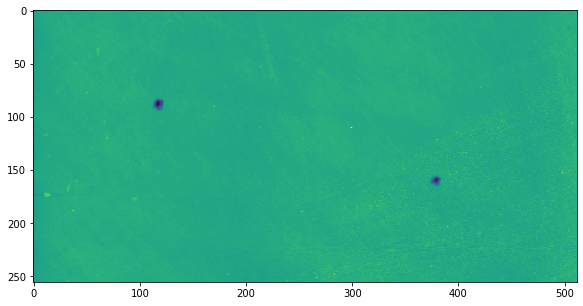

Verification artifact (2.5 PC ferrule) with a pattern consisting of 2 spot defects of 1 µm diameter, 15 nm depth, and 30 um separation distance. Produced with Nanoindentation technology, PC polished. AFM measurement report included.

The artifact is low-contrast and can only be used with Polaris or other high-resolution microscopes.

MNT-REF-D1UM artifact end face image taken with a high-end fiber microscope.

MNT-REF-D1UM artifact end face image taken with an AFM microscope.

MNT-REF-D2UM

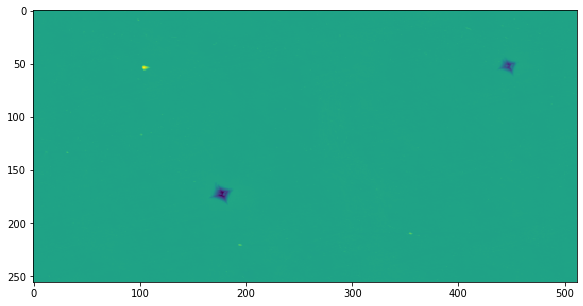

Verification artifact (2.5 PC ferrule) with a pattern consisting of 2 spot defects of 2 µm diameter, 60 nm depth, and 30 um separation distance. Produced with Nanoindentation technology, PC polished. AFM measurement report included.

MNT-REF-D2UM artifact end face image taken with a high-end fiber microscope.

MNT-REF-D2UM artifact end face image taken with an AFM microscope.